▎ Product introduction

The commonly used brands of flame-retardant PC materials are FRPC-1~FRPC-10. These 10 brands of flame retardant PC materials have different properties, namely, ultra-thin flame retardant, high flame retardant, high heat resistance, transparent, anti-aging, anti-aging, low temperature -30 degrees, anti-aging and low temperature -30 degree, increase of 10%, increase 20%, enhance 10%. It can be used in electronic device shell, lamp shell, instrument panel, printer paper feed guide, power tool shell, business instrument parts, etc.

▎ Product performance

|

特性 |

方法 |

测试条件 |

单位 |

FRPC-1 |

FRPC-2 |

FRPC-3 |

FRPC-4 |

FRPC-5 |

|

超薄阻燃 |

高阻燃 |

高耐热 |

透明 |

抗老化 |

||||

|

密度 |

ISO1183 |

23℃ |

g/cm³ |

1.2 |

1.2 |

1.2 |

1.2 |

1.2 |

|

熔融指数 |

ISO1133 |

300℃/1.2kg |

cm³/10min |

20 |

19 |

10 |

10 |

13 |

|

收缩率 |

ISO2577 |

- |

% |

0.5-0.7 |

0.5-0.7 |

0.4-0.6 |

0.4-0.6 |

0.4-0.6 |

|

洛氏硬度 |

ISO2039-2 |

1/2" |

R-Scale |

120 |

120 |

122 |

123 |

122 |

|

拉伸强度 |

ISO527 |

50mm/min |

Mpa |

62 |

60 |

70 |

65 |

65 |

|

延伸率 |

ISO527 |

50mm/min |

% |

100 |

70 |

120 |

120 |

110 |

|

弯曲强度 |

ISO178 |

2mm/min |

Mpa |

90 |

90 |

90 |

90 |

85 |

|

弯曲模量 |

ISO178 |

2mm/min |

Gpa |

2.4 |

2.5 |

2.3 |

2.3 |

2.4 |

|

缺口冲击强度 |

ISO180 |

Notched,23℃ |

KJ/㎡ |

70 |

55 |

70 |

70 |

50 |

|

热变形温度 |

ISO75-2 |

18.5kg,120℃/hr (unannealed) |

℃ |

104 |

88 |

125 |

125 |

115 |

|

软化点温度 |

ISO306 |

1kg,50℃/hr (unannealed) |

℃ |

125 |

110 |

150 |

150 |

148 |

|

燃烧性 |

|

|

||||||

|

燃烧等级 |

UL-96 |

- |

- |

0.6mmV0 |

0.8mmV0 |

1.0mmV0 |

2.5mmV0 |

3mmV0 灼热丝850℃ 1.5mm |

|

加工参数 |

|

|

||||||

|

干燥温度 |

- |

- |

℃ |

100-105 |

85-90 |

120 |

120 |

110 |

|

干燥时间 |

- |

- |

Hrs |

4-6 |

4-6 |

4-6 |

4-6 |

4-6 |

|

料筒温度 |

- |

- |

℃ |

260-280 |

250-270 |

280-310 |

280-310 |

260-280 |

|

模具温度 |

- |

- |

℃ |

70-100 |

70-100 |

70-100 |

70-100 |

70-100 |

|

特性 |

方法 |

测试条件 |

单位 |

PC-6600C |

PC-618U |

EG-8410 |

EG-8420 |

EG-8430 |

|

抗老化抗低温-30 ℃ |

抗老化抗低-40℃ |

增强10% |

增强20% |

增强30% |

||||

|

密度 |

ISO1183 |

23℃ |

g/cm³ |

1.2 |

1.2 |

1.27 |

1.35 |

1.44 |

|

熔融指数 |

ISO1133 |

300℃/1.2kg |

cm³/10min |

11 |

10 |

9 |

8 |

7 |

|

收缩率 |

ISO2577 |

- |

% |

0.4-0.6 |

0.4-0.6 |

0.2-0.4 |

0.1-0.3 |

0.1-0.3 |

|

洛氏硬度 |

ISO2039-2 |

1/2’’ |

R-Scale |

122 |

122 |

124 |

122 |

122 |

|

拉伸强度 |

ISO527 |

50mm/min |

Mpa |

60 |

65 |

70 |

90 |

120 |

|

延伸率 |

ISO527 |

50mm/min |

% |

119 |

120 |

4 |

3 |

2 |

|

弯曲强度 |

ISO178 |

2mm/min |

Mpa |

90 |

90 |

110 |

120 |

120 |

|

弯曲模量 |

ISO178 |

2mm/min |

Gpa |

2.3 |

2.3 |

3.4 |

5.3 |

7.6 |

|

缺口冲击强度 |

ISO180 |

Notched,23℃ |

KJ/㎡ |

60 |

60 42(-40 ℃ ) |

8 |

13 |

16 |

|

热变形温度 |

ISO75-2 |

18.5kg,120℃/hr (unannealed) |

℃ |

115 |

125 |

140 |

140 |

140 |

|

软化点温度 |

ISO306 |

1kg,50℃/hr (unannealed) |

℃ |

146 |

150 |

155 |

160 |

165 |

|

燃烧性 |

|

|

||||||

|

燃烧等级 |

UL-96 |

- |

- |

1.5mmV0 |

1.5mmV0 |

1.5mmV0 |

1.5mmV0 |

1.5mmV0

|

|

加工参数 |

|

|

||||||

|

干燥温度 |

- |

- |

℃ |

110 |

120 |

120 |

120 |

110 |

|

干燥时间 |

- |

- |

Hrs |

4-6 |

4-6 |

4-6 |

4-6 |

4-6 |

|

料筒温度 |

- |

- |

℃ |

260-280 |

270-290 |

280-310 |

290-320 |

290-320 |

|

模具温度 |

- |

- |

℃ |

70-100 |

70-100 |

90-120 |

90-120 |

90-120 |

▎ Reasons for choosing us

The company has a professional R & D team, customized development according to customer requirements, quickly provide samples to meet customer requirements for new product development. Professional testing personnel for each batch of products for full performance testing, products will be provided with performance testing reports, good quality, guaranteed. The company has passed ISO9001 quality management system, ISO14001 environmental management system, iso45001 occupational health and safety system, and global recycling standard GRS certification.

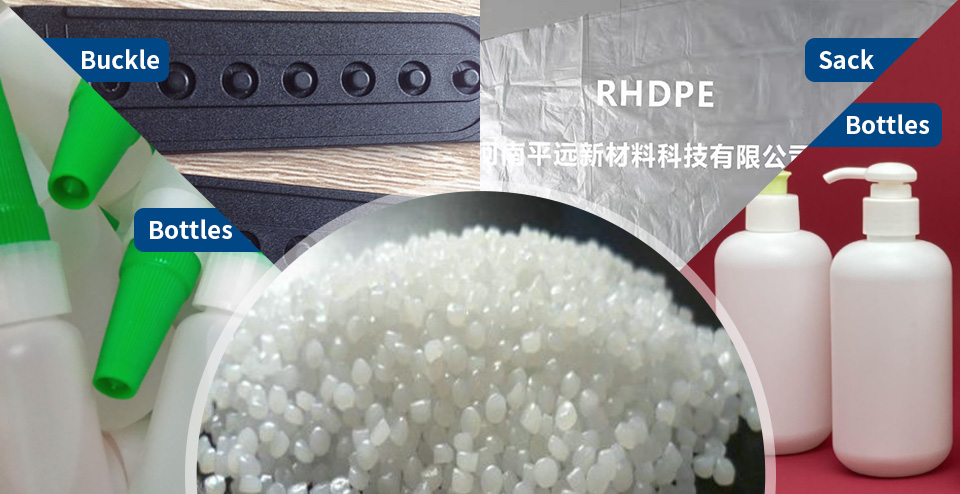

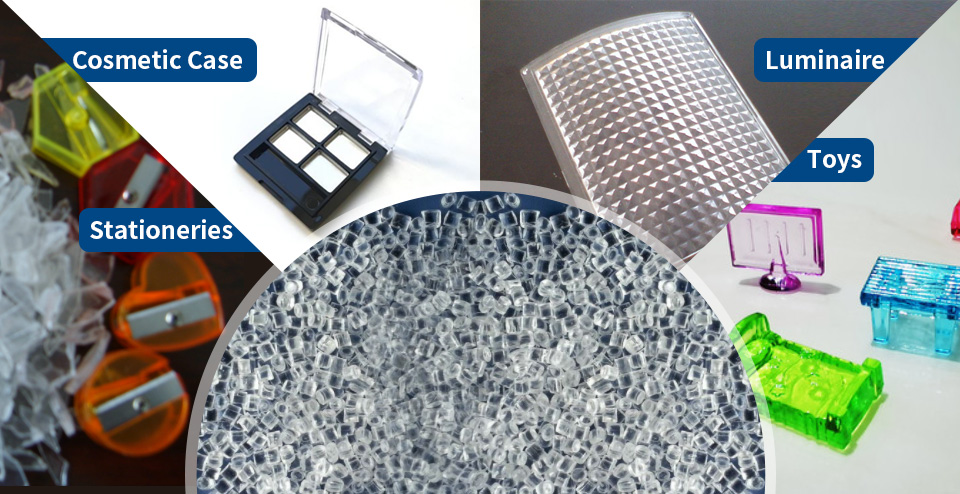

▎ Product application

Electronic device shell, lamp housing, instrument panel, printer paper feed guide, power tool housing, business instrument components, etc.

Call us

Call us

Product Detail

Product Detail